Bag OEM - various of custom bags

Pre-production Planning for Bag Design:

Before mass production of bags, pre-production planning is required, such as designing sketches of the bags, selecting and cutting fabrics, and confirming various details of the bags.

Customized Bag Design

Inquire about the type of customized bag, product characteristics, and packaging options. Provide product proposals and initial quotes (a physical sample is required to estimate the price).

Fabric size and cutting confirmation

Confirm the amount of fabric needed, which can include selecting from several existing fabrics or ordering additional fabric (with a minimum amount required), and assist in the layout of the bag design.

Confirmation of bag details and additional requirements

Select zipper styles, hardware accessories, and thread colors for sewing. Additional requirements for bags can also be requested, such as embroidery, printing, transfer printing, or leather branding.

Bag Sampling

Quickly provide various evaluations based on customer needs/proposals and adjust sample costs based on the complexity of the design.

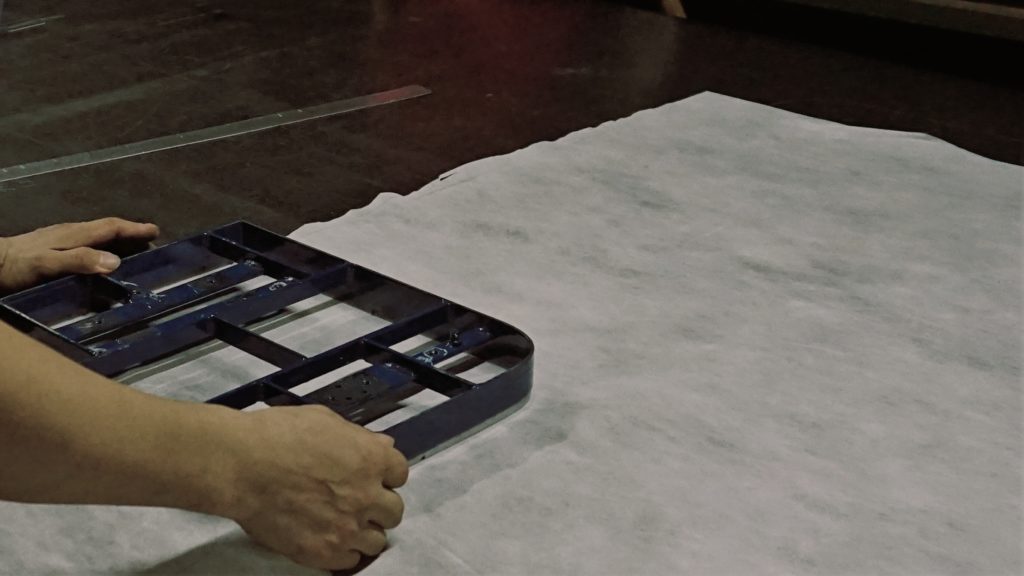

Bag Pattern Making

Divide the design sketch into various parts, such as the main bag, inner bag, front bag, and shoulder strap, etc. Each part is handmade and recorded on paper cards with the size of the material pieces. The parts are then sewn together to gradually form the bag sample.

Actual Sample Confirmation

All backpack materials, such as buckles, zippers, and shoulder straps, are assembled together with the backpack fabric or leather. This becomes an actual bag sample that customers can see and inspect.

Bag Production and Shipping

Purchase necessary materials, enter the bag production schedule, conduct quality inspections, and arrange shipping according to customer needs.

Bag Production Schedule

After the sample is completed and tested or the customer decides to finalize the order, production begins. The bag factory purchases a large amount of fabric and necessary accessories (such as zippers, magnetic buckles, and other hardware), uses paper templates and cutting machines to cut out the fabric according to the design and different sizes and shapes, and enters the production stage to mass-produce the bags.

Bag Shipping Arrangements

After inspecting the bag quality, the bags are shipped according to customer needs, such as through overseas trade or shipping. The bag products are delivered to the requested location.

In the production process of the same order, there is a minimum quantity requirement for both the fabric part (including the main material, lining, accessories, etc.) and the material part (zipper, hardware, label, etc.) as well as the backpack production related machines. Additionally, because each bag design has different materials, accessories, and different patterns, the minimum production quantity for each bag design is not the same. If you have any customized bag requirements, please feel free to contact us.

You can fill out an online form or call us at +886-2-2267-3108. We will be happy to assist you!